How To Buy Wood

When learning how to get started woodworking, you will soon take the much-anticipated trip to the lumberyard or the specialty hardwood store to buy the stock for your first project.

Page Contents

Learning the Lumberyard Lingo

Buying wood for the first time can be a daunting experience. I didn't know there's an entirely different jargon that goes with the lumberyard.

Going to a lumberyard or hardwood store is a lot like going to a bakery in a foreign country. You can see the bread and pastries, but you don't have the words to tell the salesperson exactly what you want. You can point and use just enough of the local language to make yourself look like an idiot. Then they answer you in a strange dialect and act as though you should know what they are saying. It can be an intimidating and frustrating experience.

On my first lumberyard trip, I had no idea there were so many variations in a board! I told the flannel-clad sales guy I needed a one by six by 6 foot Maple board. He just looked at me and said:

"Well, I ain't got 1 x 6, would a four-quarter or eight-quarter do? I have some eight-quarter rough-sawn planks that you could have re-sawn into four-quarter. Oh, and are you looking for it quartersawn or riftsawn? Surfaced or skip-planed?? How many board feet did you say?"

Stay with me to the end of today's post so you can confidently walk into a lumberyard or hardwood store and make your purchase knowing what you are buying exactly. You will also know how to calculate the price based on board feet.

I hope you find it helpful.

Helpful hint: There can be a big difference in price and variety of wood available depending on the type of store.

- A big box store like Home Depot or Lowe's is generally going to have a limited selection, like a fast-food restaurant.

- A specialty hardwood store is like a fine dining restaurant with an extensive menu.

Lumberyards or lumber mills that process the Hardwoods on-site can be like going to a grocery store where stock on hand is limited, but they have a whole bunch of it. You may have to be willing to search for what you want.

The Wonderful World of Wood

Hopefully, we all know that wood starts as a tree or "timber," and once cut and trimmed, it is called a "Log."

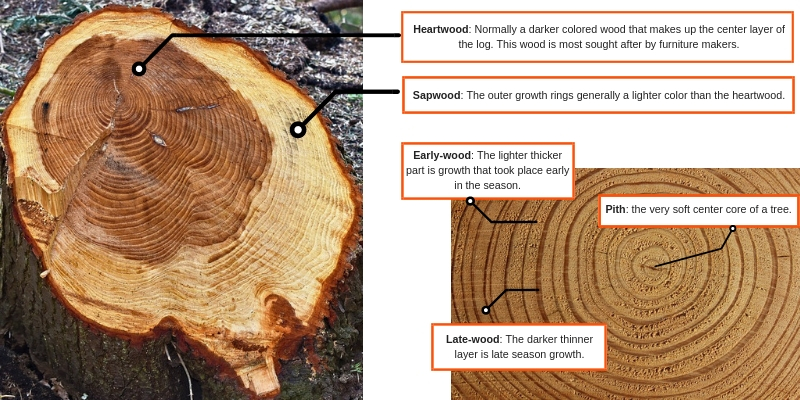

Types of wood in a log:

Board terminology:

- End grain is the small end of a board where you can see the rings of the tree.

- Edge grain is the long and narrow sides of the board.

- Face grain is the large flat sides of the board.

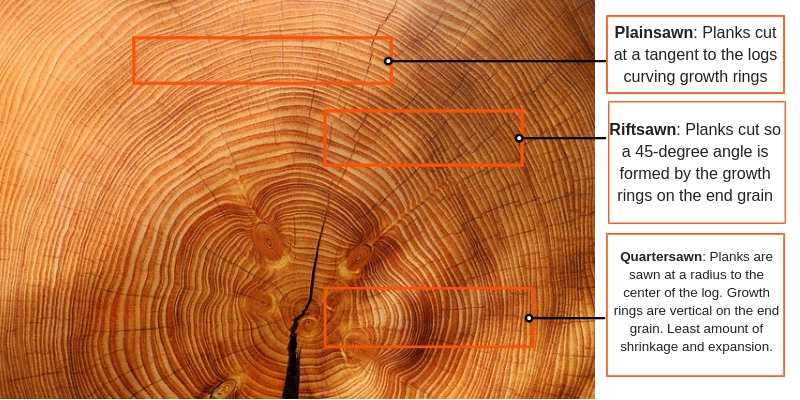

Types of Boards or Planks:

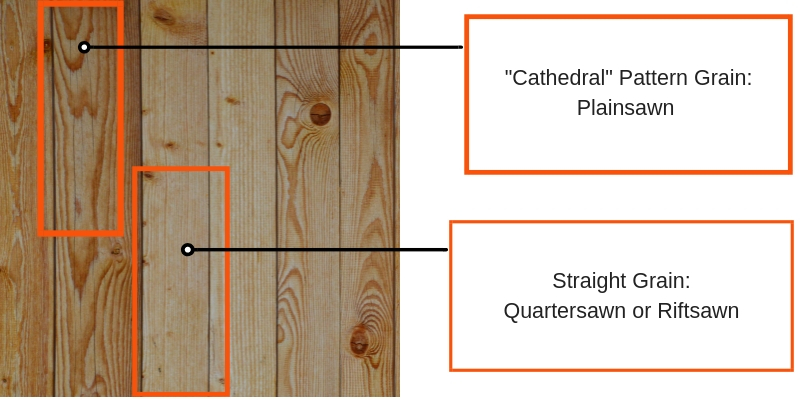

Plain-sawn: planks are sawn at a tangent to the curve of the log. Notice how the growth rings form an even curve across the end grain. Face grain will create "Cathedral" patterns.

Quartersawn: planks are cut at a radius to the center of the log. The growth rings can be seen almost vertically across the end grain. The face and edge of the board will have straight grain. This type of cut will shrink and expand less than others.

Rift-sawn: the end grain of these planks show growth rings at a 45-degree angle. The edge grain and face grain run straight.

Board surfaces:

Rough-sawn: planks that have only been cut at the lumber mill. No squaring or smoothing has been done.

Skip-planed: planks that have been partially smoothed on one side to show some of the wood grain. It can also be called "hit-and-miss planing."

S4S (Surfaced on 4 Sides): planks that are planed smooth on both faces and both edges.

Helpful hint: For anyone wanting to go "down the rabbit hole" with understanding hardwood grades and the rules for evaluating. Check these links out: NHLA Rules Book (National Hardwood Lumber Association) and the NHLA website.

How to Calculate Board Feet

Rough-sawn boards are measured in one-quarter inch increments.

- A four-quarter board will be 1 inch thick.

- An eight-quarter board will be 2 inches thick and so on.

One board foot is equal to 144 cubic inches. So "board feet" are the volume of the board, not its length.

So, a board 1-foot long could contain more than one board foot.

Examples: If you have boards with the following measurements

12-inch wide x 12-inch long x 1-inch thick= 144 cubic inches or 1 Board Foot

or

12-inch wide x 12-inch long x 2-inch thick= 288 cubic inches 2 Board Feet

more examples:

6 inch x 24 inch x 1 inch = 144 cubic inches =1 Board Foot

or

1 Board Foot = 6 inch x 12 inch x 2 inch = 144 cubic inches

So you see, the dimensions of a board can change a lot, but the number of board feet can remain the same. It's all about measuring.

Knowing this, you can calculate in advance how much the wood for your project will cost.

A straightforward calculation for board feet in a plank is, multiply thickness by length and the width (all in inches) and divide by 144.

Thickness x Length x Width (all measurements in inches) ÷ 144= Number of board feet

Example: 2 x 68 x 9 ÷ 144 = 8.5 Board feet

Whew!

You now have the lumberyard lingo at your fingertips so you can go and buy wood with confidence.

You can even practice evaluating the different cuts of wood everywhere you see boards!

A great place to practice is on a fence.

Usually, you'll find every type of board making up an average plank fence.

What do you think of this topic? After reading it, I hope you're not "board."

I'd love to hear from you in the comments! Check out more information at https://howtogetstartedwoodworking.com/home/

My husband recently purchased some wood for some kitchen shelves he wants to build. He asked me what kind of wood I wanted and I showed him something that looked nice to me, he said, “that’s not real wood,” he showed me three different types of wood that he recommended for our shelves and explained why each would fit well in our kitchen.

It’s still a blur to me. 🙁

Next time, I go shopping for some wood with my husband, I’ll make sure I have a copy of your article with me to sound like I really know what I’m talking about…that will certainly impress my husband! 🙂

Thank you for this great article. When I realize that the harwood floors and wood shelves in our homes were once trees, it’s truly amazing to me!

Thanks for your interest! Wood is a truly amazing and renewable resource. I hope your kitchen project turns out well. Enjoy the process Christie!

I did property management for 12 years and had to hire people for all sorts of remodeling type projects and often times I would be sent to Lowe’s or Home Depot for materials. That was truly exciting considering i know absolutely nothing about home repair, remodeling, or maintenance!

I have had to purchase wood before and didn’t know the difference between any of them. If I ever have to purchase wood again, I’ll have your post to refer to!

Hey Chas, Thanks for taking time to comment. I hope you continue to find valuable information here!

Cheers!