Page Contents

About Circular Saw Blades

“Oh my gosh! There are a zillion different circular saw blades out there! Which circular saw blade do I need?”

No matter what saw you have in your possession, the saw blade is the main feature that will affect how well you can cut wood.

2 Questions To Ask About Saw Blades

For the beginner woodworker, and for anyone else choosing a saw blade, there are two key questions:

- The application or “what are you going to cut?”

- The Finish or “how smooth do you want the finished cut to be?”

In this post, I will identify the parts of the saw blade and the different terminology used in the saw blade marketplace.

Then we’ll take a look at the different types of saw blades and their uses.

Having this knowledge will eliminate some confusion when shopping for a saw blade and help you get started woodworking sooner.

NOTE: Although I recommend a 7 ¼ inch circular saw for beginners, information in this post is the same for any size circular saw blade.

Circular Saw Blade Parts

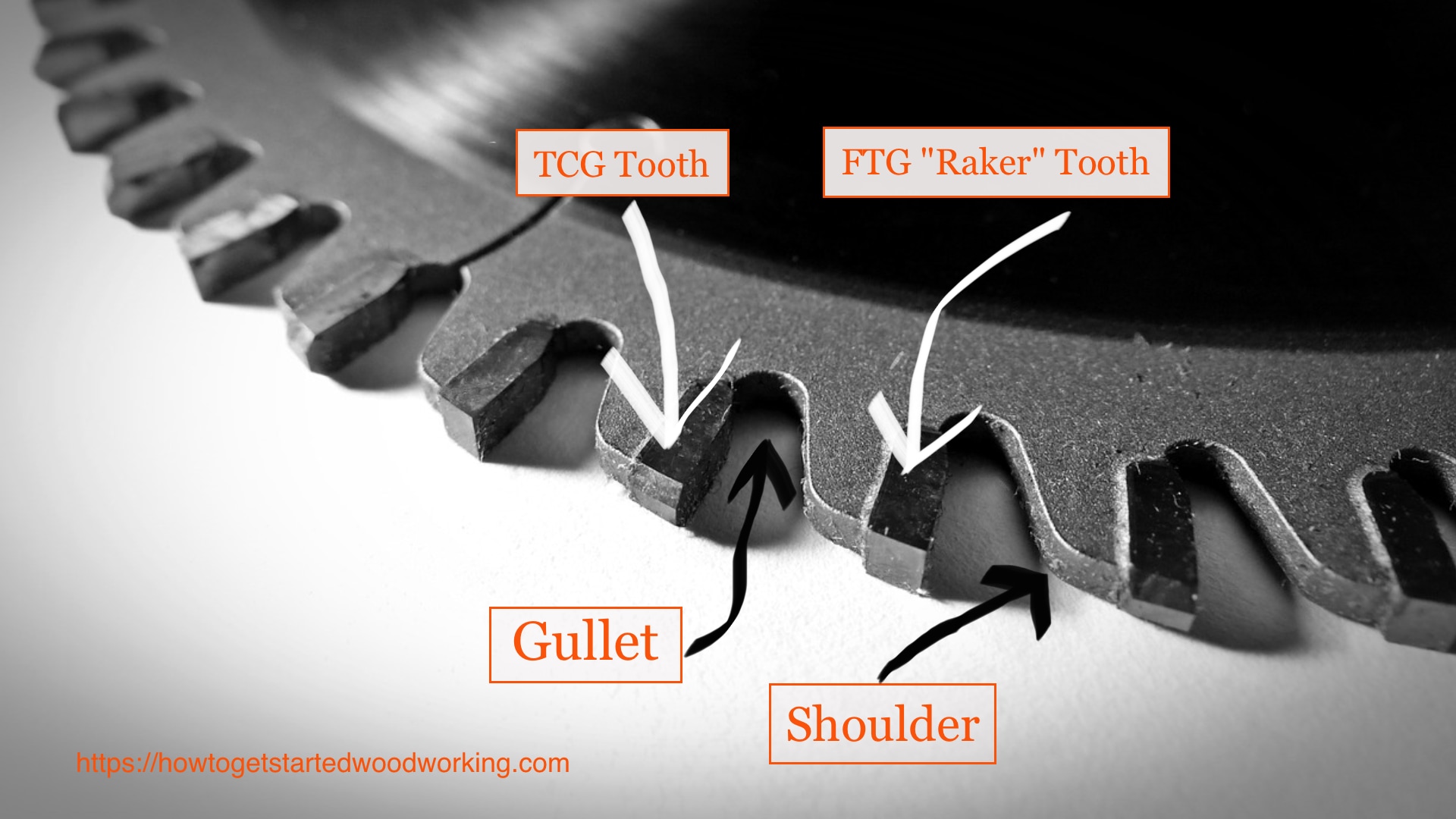

Teeth

The sharp hardened steel or carbide tips on a saw blade. Saw blade teeth contact and cut any material for which the blade is designed.

Number of Saw Blade Teeth

- Typically the more teeth you have on the saw blade, the cleaner and slower your cut will be.

Shoulder

A part of the saw blade directly behind the tips of the teeth that kinda looks like a shoulder. The shoulder is the primary support behind the carbide tips of your saw blade.

Gullet

The inside curve of the saw blade between the teeth. This is a carefully engineered space for removing woodchips while you cut.

- Fast cutting blades with fewer teeth tend to have larger a gullet. (e.g., general-purpose ripping saw blades)

- Saw blades with a lot of teeth will have a smaller gullet and cut slower. (e.g., finishing or plywood saw blade)

Kerf

When you make a cut, the width of the material your saw blade removes is the “Kerf.”

- Standard kerf for a circular saw blade is 1/8 inch.

- Thin kerf blades that measure about 3/32 inch are also available and very useful depending on your application.

Plate

A large flat steel disc from which the saw blade is made.

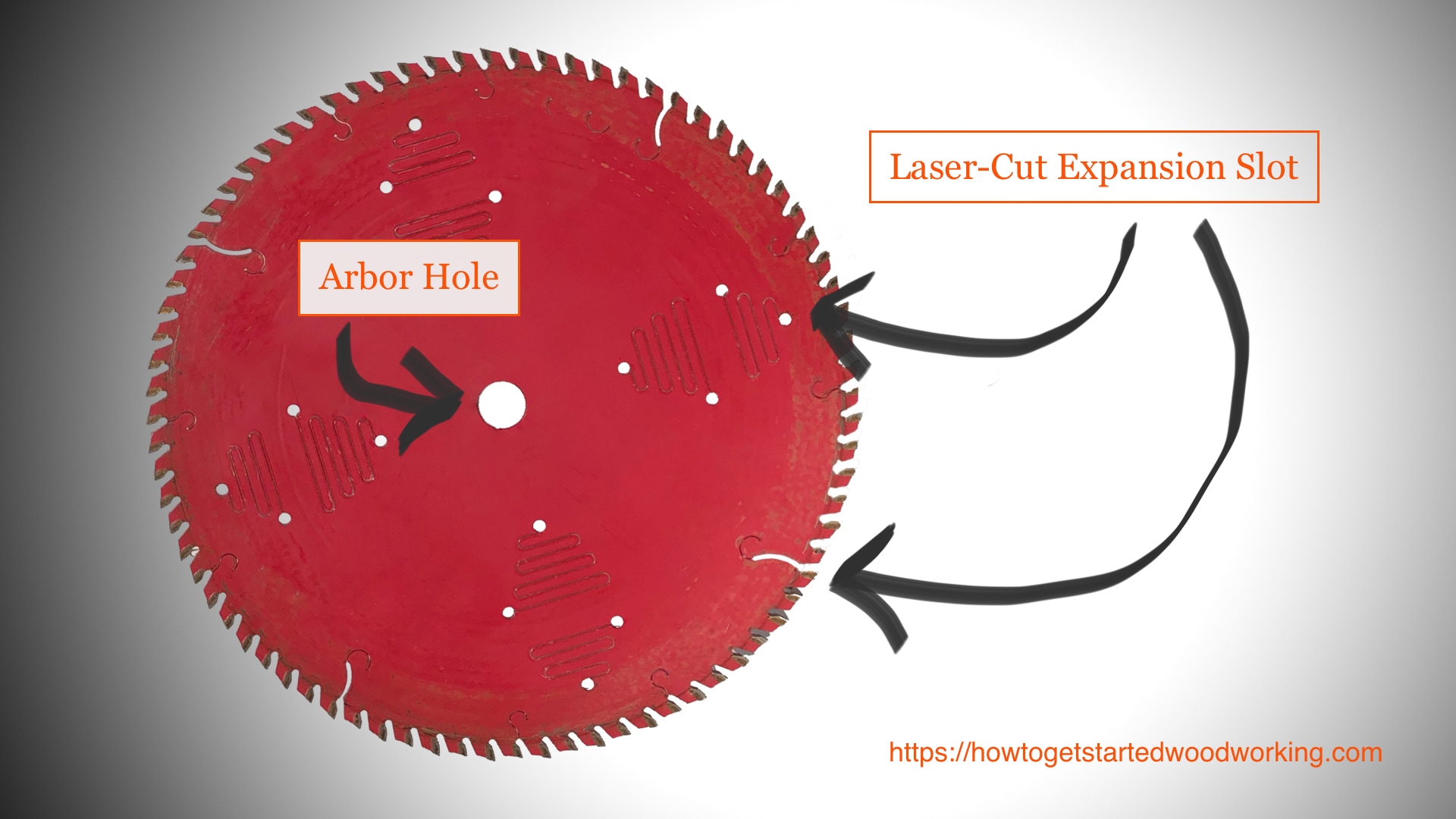

Arbor Hole

The center hole in the plate of the saw blade that allows you to mount the saw blade on the "arbor" of the circular saw.

Expansion Slot

Look for saw blades with laser-cut expansion slots.

As you cut through material, a great deal of heat is created from friction.

Expansion slots prevent saw blades from warping due to this heat. They are engineered and laser-cut into the blade to keep it straight and true.

About Saw Blade Teeth

There are four types, and many configurations, of Circular saw blade teeth.

To view the tooth configuration, hold the circular saw blade vertical and parallel to your line of sight with the teeth pointing at you.

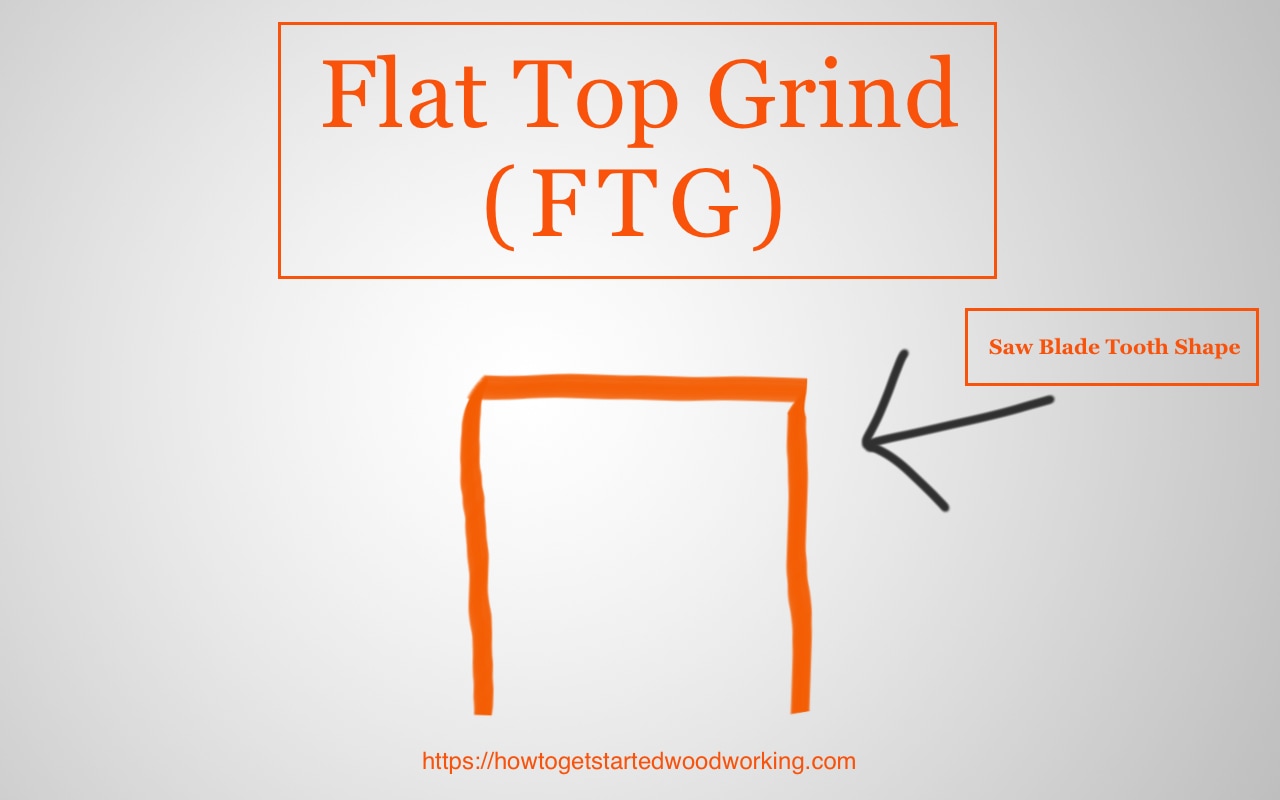

FTG (Flat Top Grind)

Every tooth on this saw blade is perfectly square. As the blade rotates, each tooth acts like a small wood chisel, leaving a less than smooth cut.

FTG saw blades do cut quickly and are suitable for ripping with the grain of the wood.

NOTE: An FTG tooth is often used as a “raker” on combination saw blades.

- Pros: Straight cutting blades that are both strong and simple to maintain.

- Cons: The blades require a lot of power and create a lot of “tear-out” as they go through the wood.

Raker Tooth

An FTG saw tooth that cuts a "kerf" with a flat bottom.

ATB saw blades without a "Raker tooth" leave a kerf with a small V shape on the bottom. Sometimes this is not what you want when cutting a groove.

The addition of a "Raker tooth" to the ATB blade makes a very square and clean grooved cut.

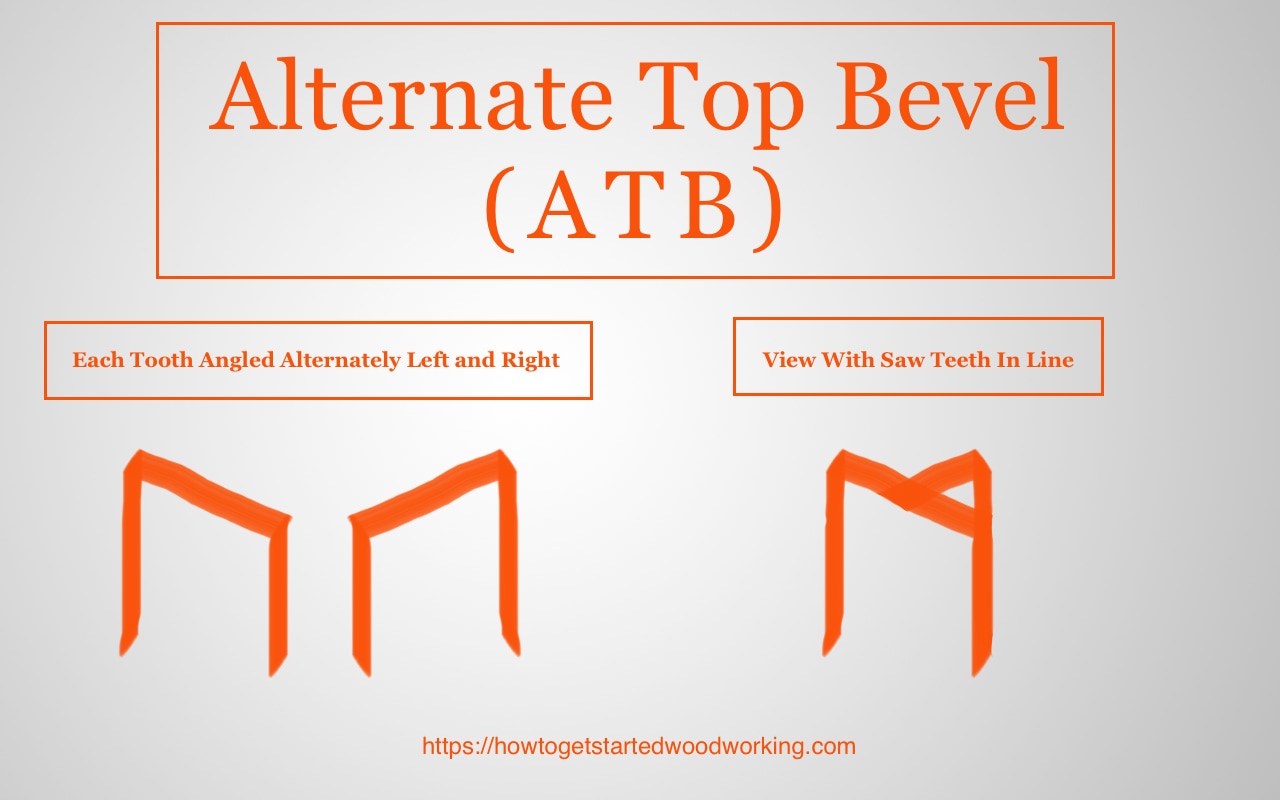

ATB (Alternate Top Bevel)

Every other tooth is angled in the opposite direction. As the blade rotates, each angled tooth slices the wood leaving a nice clean cut.

Viewing across the tips of the teeth in line, you can see a V shape. The angle of the teeth can vary on saw blades for different purposes.

Generally, the steeper the edge of the teeth is, the cleaner the cut.

- Pros: ATB blades are smooth cutting and have efficient sawdust removal.

- Cons: Sharpening equipment is expensive, and blades tend to get dull slightly faster.

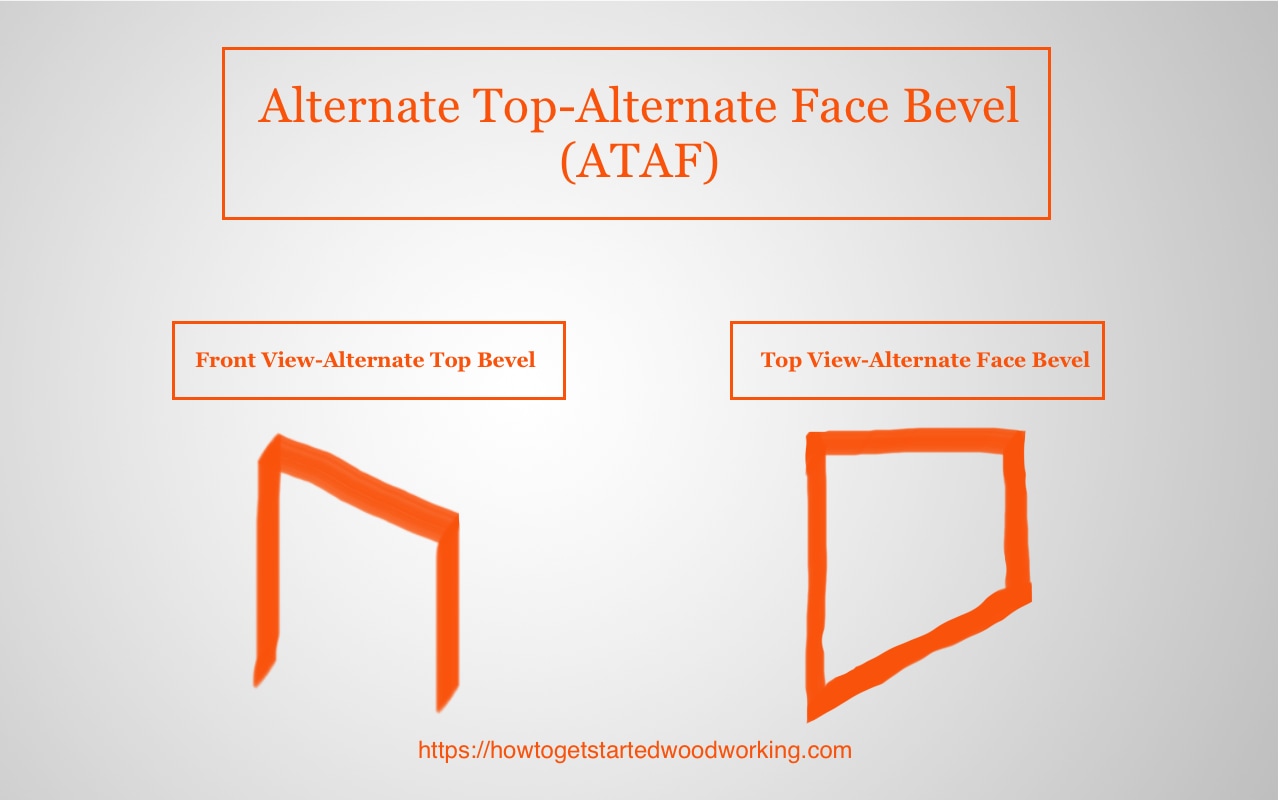

ATAF (Alternate Top Alternate Face Bevel)

Not only is the top of the tooth angled, but the Face of the tooth is angled as well, adding even more smoothness and efficiency for certain types of material.

- Pros: Just like ATB blades, they are smooth cutting and have efficient sawdust removal.

- Cons: Sharpening equipment is expensive, and blades tend to get dull slightly faster.

ATBR (Alternate Top Bevel with Raker)

Also called an “all-purpose” or “combination blade.” As you view the ATBR type of circular saw blade, you will note a series of four ATB teeth followed by a single FTG “raker” tooth.

This type of blade is called a "combination" or "all-purpose" blade because it can be used for both ripping and cross-cutting. Which makes them a very popular circular saw blade.

- Pros: Just like ATB blades, they are smooth cutting and have efficient sawdust removal.

- Cons: Saw blade Sharpening equipment is expensive, and blades tend to get dull slightly faster.

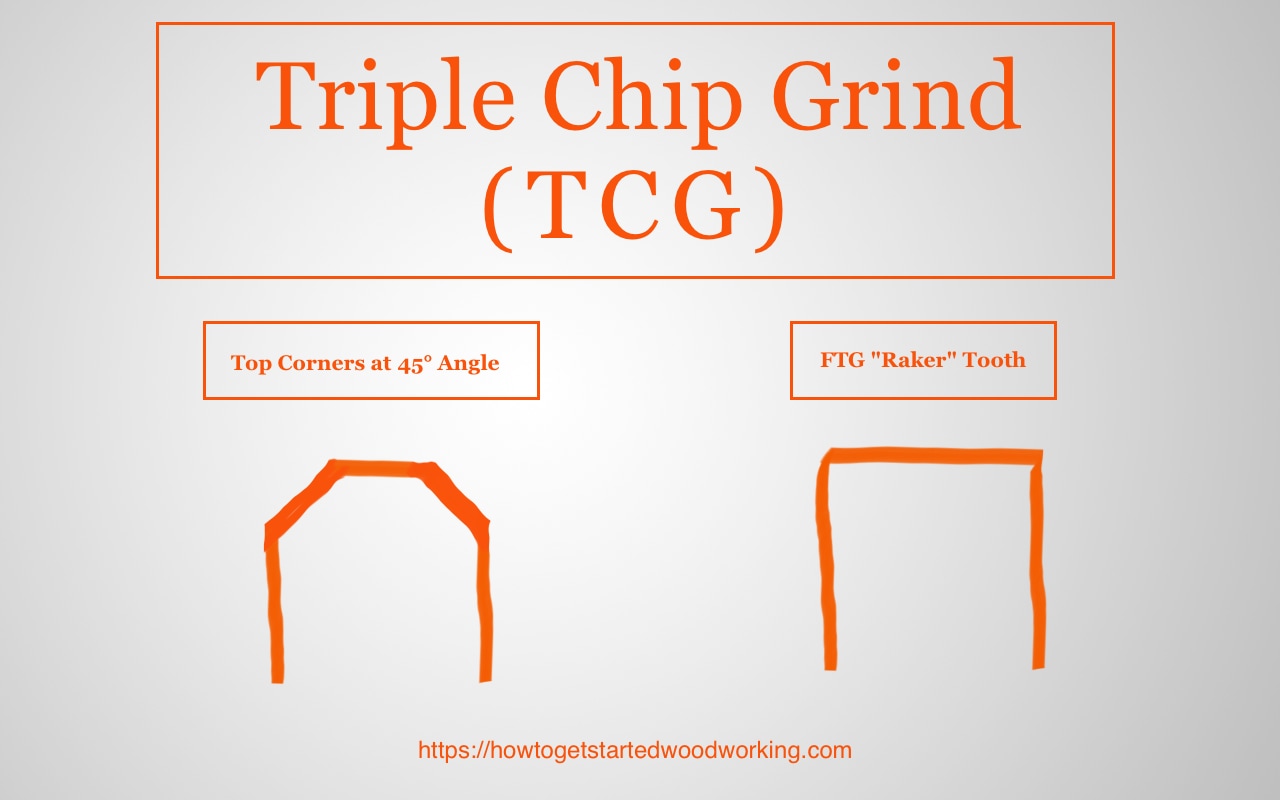

TCG (Triple-Chip Grind)

This one sounds more like an ice cream flavor to me.

Still, you will note alternating FTG or perfectly square teeth and chamfered teeth, or otherwise square teeth with the top corners chopped off at 45°.

As this blade rotates, the chamfered tooth creates a rough cut, and the flat tooth chisels a clean corner producing a smoother result.

TCG saw blades are often assigned the task of cutting ferrous metals, as well as aluminum, brass, Corian, and fiber cement products.

- Pros: TCG blades are terrific at straight cutting and do not dull too rapidly.

- Cons: Sharpening requires precision equipment.

NOTE: As manufacturers engineer better saw blades, you will find longer acronyms that describe the combined types of blade teeth.

These new combinations result in complex but very useful applications.

For example, Makita makes a framing sawblade labeled ATAFR (Alternate Top Alternate Face with Raker)

Steel Circular Saw Blades

Originally when saw blades were first conceived, the teeth were cut from the plate of steel, and that was as good as it got for some time. Later the teeth were hardened by heating and cooling the steel.

Carbide Tip Saw Blades

Tungsten and cobalt are used to produce one of the hardest man-made alloys in existence, the alloy “tungsten carbide.”

The unique qualities of tungsten carbide give saw blades a lifespan 50 times greater than their old steel counterparts.

Carbide tips are manufactured separately from the steel plate. Later, the carbide tips are brazed on to the steel plate saw blade.

Hook Angle

The saw blade hook angle can be viewed by holding the saw blade vertically and perpendicular to your line of sight, so you’re looking at the broad flat surface of the blade.

The hook angle is how far forward or backward the saw blade teeth are “leaning.”

You can also think of it as the angle that each tooth will enter that wood you are cutting.

NOTE: A saw blade tooth striking the wood at a 22° Hook angle will produce a better cut than a saw blade tooth with a 0° hook angle that enters the material completely flat.

Why is hook angle important?

For ripping and cross-cutting wood, a steep angle allows the saw blade to grab the material and pull it into the blade.

This can be fine for fast cuts when ripping wood and cutting softer materials.

When working with hard materials like metals, a negative hook angle up to -5 degrees is used to prevent any stock from self-feeding into the blade.

It gives the saw operator much greater control and safety.

Bottom line: Read the information provided for each saw blade and its recommended purpose. Using the proper saw blade for each material keeps you safe!

Circular Saw Blade Types

Choosing the right saw blade for the job.

As you begin woodworking, you may find your projects call for more than standard lumber. You may need to cut melamine, hardboard, or even a plastic laminate.

Framing saw blade

Usually have 24 teeth and use ATB or ATBR construction. Those who work in the framing industry are building the internal structure of buildings.

All of the “framing” will be covered by wallboards and ceilings, so there is little concern for clean and pretty cuts on the 2 x 4 and 2 x 6 framing materials.

These blades are inexpensive and can make multiple cuts rapidly.

Finishing saw blade, paneling blade

These blades usually have 40 teeth or more in an ATB or ATAF configuration. They are intended to make clean, smooth cuts that will require little effort to “Finish,” hence the name.

Combination Saw Blade

Saw blades designed for both ripping (cutting wood with the grain) and crosscutting (sawing wood across the grain) generally have an ATBR tooth design.

Plywood, hardwood, chipboard, MDF, laminate, melamine, veneer Saw Blade

There is now a wide variety of saw blades specific for almost every type of material. Each saw blade may have its own unique tooth configuration that is engineered for the particular product it is designed to cut.

Given the cost of building materials, I recommend purchasing the saw blade that will guarantee you the best result for your project.

It would be unfortunate to ruin a $50 sheet of birch plywood with the wrong saw blade.

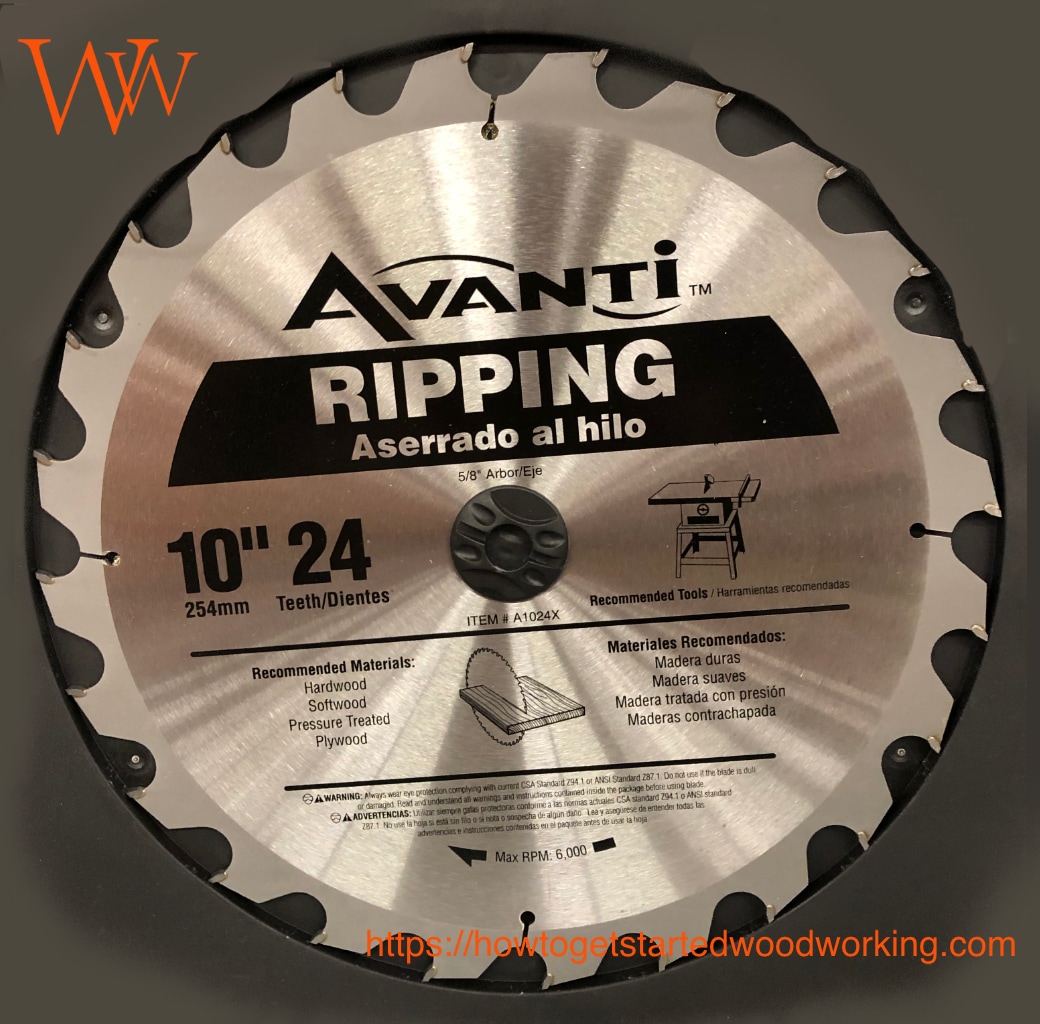

Ripping Saw Blade

Designed specifically for cutting along the grain of the wood.

Ripping saw blades traditionally have an FTG tooth configuration.

Newer saw blades have several different tooth configurations.

The completed cut is generally quite rough. This type of cutting is often used when framing structures, or reducing large pieces of wood stock into smaller sizes.

Crosscutting Saw Blade

Tooth design is usually ATB for crosscut saw blades. Remember, the more teeth on your saw blade, the smoother you’re finished cut will be.

Thin Kerf Saw Blade

These saw blades conserve energy and cause less waste. Thin blades pass through wood with less effort, but often have a compromise in a reduced smoothness of the cut.

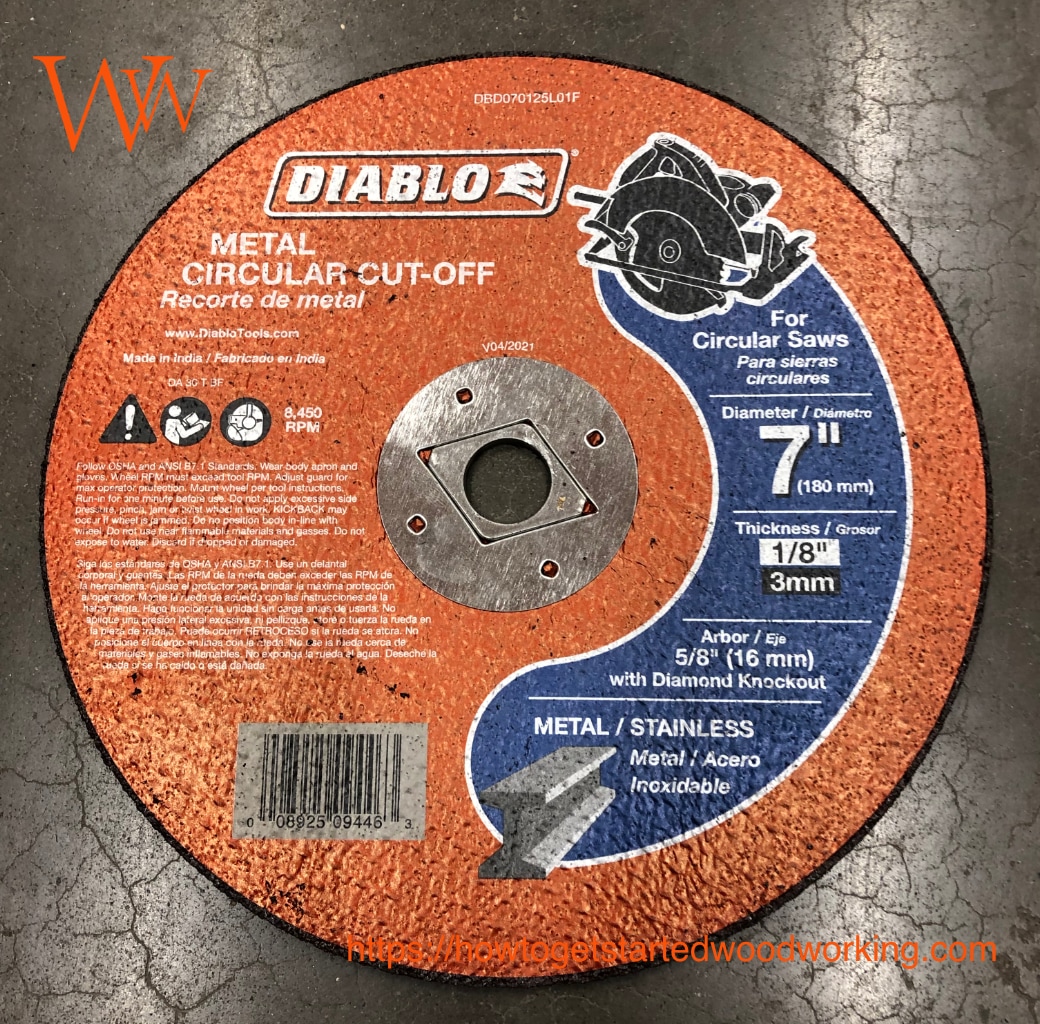

Metal Cutting Saw Blade, Ferrous metal cutting saw blade, Sheet metal cutting saw blade

Each material will have a saw blade engineered to cut it safely. Metal cutting blades may have a different Hook angle depending on the type of metal.

NOTE: When cutting metal, it is imperative to use the proper saw blade for each material.

Concrete, Brick, and Tile Cutting Saw Blades

Several types of blades are available for concrete cutting. Abrasive blades and diamond blades are the most common.

Abrasive Saw Blade

Abrasive saw blades look more like a disc with no teeth. They cut with silicon carbide or aluminum oxide has the abrasive material.

Continuous Rim Saw Blade

A type of Diamond edged blade used for cutting tile or slate. Industrial diamonds are attached to the edge of the blade and create a precise finish. It is important to note that some of these blades may require a wet saw.

Turbo Rim Saw Blade

Another diamond-edged blade, the turbo rim, has a serrated edge and is suitable for cutting through brick mortar and concrete. Not recommended when you want a clean, smooth finish.

Segmented Rim Saw Blade

The most aggressive of the diamond-edged blades. Each segmented section is divided by a gullet that works the same as any other circular saw blade.

They are best for powering through brick and concrete, where there is no concern for a pretty finish cut.

Saw Blades To Have On Hand

I recommend keeping a 3 types of saw blades on hand.

1-Framing Blade

2-Combination Blade

3-Finishing Blade

NOTE: The saw blades included with a circular saw purchase are usually 24 tooth framing blades. If that is all you need, then you are set!

Conclusion

I hope you now have a better understanding of saw blades and the terminology that goes along with them.

Having the right saw blade on hand is essential for:

- cutting wood quickly and accurately

- cutting anything safely

- enjoying each project you create

Information in this post should give you a good grasp of what you need to look for as you get started woodworking with a circular saw.

This is my third post in what is turning out to be a series of posts about circular saws.

- The first post is about how to choose a circular saw.

- In the second, I reviewed several good circular saws for a beginner woodworker.

- Next, check out my post on how to clean saw blades.

If you have any questions, be sure to leave them in the comments below, send me an email, or even connect on Facebook.

Thanks for reading!

https://howtogetstartedwoodworking.com

So you know...As an Amazon Associate I earn from qualifying purchases.

I really like that you defined the components of the circular saw blade for newbies like me! My friend just got into woodworking and has been using a circular saw blade, but I have been a bit intimidated by them. Do you have any advice for overcoming the fear of using one? I see that using the right blade for the job is very helpful. Can you suggest in other posts some great projects for newbies? Thanks!

Hello Melinda, and thanks so much for commenting!

I’m glad you found my post informative. Regarding overcoming fear of using a circular saw, I recommend gaining understanding of how the tool operates. A lot can be gained from user manuals that come with each tool. Having knowledge and understanding of how the tools work, converts your fear into respect and confidence. Be sure to follow all the wood shop safety rules and you will find yourself ripping boards in no time!

I did write a post about projects for newbies that you can check out here: Excellent Beginner Woodworking Projects and Plans—Book Reviews I hope you find these helpful too.

Best regards,

Greg

Hey Greg,

I just read your article on how to clean saw blades, and I am really glad I did! I never would have thought of using baking soda to clean my saw blades.

It’s good that you gave some guidelines as to when the blades should be cleaned, and why. I also did not know that oven cleaner could cause the carbide tips on the blades to fly off when in use. That is scary.

Do you recommend a regular schedule for cleaning the blades, even if they look fine? Like every 3 months? Or should we just clean them as we see the resin on the blades start to build up?

Michael

Hello Michael!

Thanks so much for reading and commenting! I’m glad you found my posts helpful. Cleaning your saw blades is only necessary when you see they need it. So if they look fine, then they most often are fine. If you can see the brown build up on the tips its best to clean it. Of course, it’s always best to inspect the blade before cutting rather than waiting until you see smoke rising from the wood to make that determination.

I have had days when I had to clean a blade a couple of times because I made mistakes that burned the wood. (Usually when trying to cut 4′ x 8′ sheets without a helper)

Have a great day!

Greg

Hi and thanks for this informative and interesting article on Circular Saw Blades.

After reading your Post I was amazed how much detail there is on Saw Blades. I have to agree that purchasing the right saw blade for the right job is so important because of the cost of materials. You lead me on the right path for the job I need to do and helped me with my understanding of saw blades.

Hi Marc!

Thanks for letting me know this article was helpful! It is always nice to hear from my readers.

Have a fantastic day!

Greg

I am a novice in woodworking and have chosen as a hobby to make my retired life interesting. Frankly I did not know, till I read your article, that there so many varieties of circular saws available. I will bookmark this site to reference when I need to decide the right type of circular saw for my application. But I will go with your recommendation of the 3 types of saw blades to start off. I would appreciate if in your future posts you could give some practical tips with examples of difficult cutting situations and the right type of blade to solve it.

Hi Srinivasan, thank you for taking the time to comment. I really appreciate it! I’ll make an effort to give more practical tips for using the tools I recommend.

Best regards,

Greg

Hi, Greg.

Thanks for sharing your views on Circular saw blades. Wow, there are so many variants to choose from. Once we know the exact quality of wood to be sculptured it is easy to choose the master saw blade. The technical details are very useful. Please tell if extra precautions are needed to store these circular saw blades?

Warm Regards,

Gaurav Gaur

Hello Gaurav!

Thank you for reading and commenting! What an excellent question you have asked about storing circular saw blades. Yes there are precautions you should take to carefully store your circular saw blades. Because tungsten carbide is one of the hardest materials on our planet, it will very likely scratch or cut anything it comes in contact with. Also, if you have several carbide tipped blades, you want to prevent the carbide tips from touching one another because the carbide from one blade can dull the tips of another. This can shorten the life of your saw blades. There are commercial storage cases available, or you can simply separate them with pieces of cardboard or even make a sleeve for each blade from cardboard much like our vinyl LP records back in the day.

Thanks again!

Greg

Your article was an excellent primer on the different kinds of circular saw blades and the specific purposes they are designed for. After reading your article I was much more informed than I ever was about circular saw blades.

The design features that caught my attention were the laser cut expansion slots. I never thought about the problem of the blade expanding through heat. This was an elegant solution. The other design features such as the profile of the edge of the blade as well as the coating materials gave me a clear understanding on what goes into circular saw blades used for cutting a variety of materials as well as the quality of cut desired.

I had no idea there was such a variety of designs that are still evolving for providing improved cutting performance. When we had granite counter tops installed in our kitchen some of the pieces were cut in the shop. The installers cut many of the slabs in our back yard to size. I was impressed how smooth the edges were and the speed at which they were able to cut through such a hard material like granite. Perhaps the circular saw blade used was the continuous rim diamond coated edge that gave that smooth finish. Am I correct? I think they also used water to keep the blade cool.

Thanks for educating me on circular saw blades. When I look at a circular saw blade again I shall be looking to see what the edge design happens to be and have a better understanding as to what it’s purpose is.

Edwin

Thank you Edwin!

I’m glad you found my post informative. The technology behind some of these otherwise mundane tools is quite impressive.

I hope you are enjoying your new granite counter tops. I think you are correct in your assumption that a continuous rim blade was used to cut the granite. I have never done any work with stone so my understanding in that area is limited. I do know that a water cooled saw is very common for cutting stone and ceramic building products.

Best regards,

Greg

Hi,

I never even knew Circular Saw blades have this much information until I came across your post. Thanks for providing the technical details, it really comes in handy. I sent the link to your post to a friend of mine who is about to go into wood working. Please can you recommend any projects or training for beginners too? And which of the circular saw blades would you have any beginner to have first?

Hello Isanren,

Thank you for stopping by and Reading my posts! I’m glad you found it informative and thank you for sharing it with your friend. It’s a good idea to start with a simple project as a beginner woodworker. I wrote another post about this that you can access here:Excellent Beginner Woodworking Projects and Plans—Book Reviews there are a bunch of options that I am sure will help. There is no Single answer to which circular saw blade you would need first, it just depends on what you are planning to do. It may be that jigsaw would be the one tool you would need to make your first project. You can check out a post about jigsaws too.

Have a great day!

Greg

Wow, I could peruse through here for a while and I haven’t done much woodworking, but you’re breaking down all these topics so well I feel like I could get back at it with much more skill. This post has more detail about saw blades then I think pretty much anything I’ve read in a while. I would like to make some table utensils out of wood but didn’t even know where to start. However, after reading your blog I think I found my wood working guru.

Hey John,

I appreciate your remarks. I’m glad to hear you like to get back into woodworking. If you want help getting started with those table utensils, let me know what you have in mind and I’ll see if I can point you in the right direction.

Have a great day!

Greg

Well thanks a lot for this post as this has clarified my knowledge about circular saw blade. I love woodworking and I have to be honest that although I like it there is a lot I don’t know about it. I have made use of several saw blades but I have not really done enough research on them to know the right one for the job and they were pretty expensive.

I won’t say they were a waste of money because they still got the job done but maybe not the way I wanted them to. I have become more knowledgeable by just reading this post. Job well done.

Hi Manuel,

I’m glad you found some useful information in my article. One of the nice things about buying saw blades is they do last a long time. So, even though they might not have been perfect for your last project, you’ll undoubtedly find a good use for them in a future project.

Cheers!

Greg

This is very helpful information to have as we catch up on old projects around the house (and create a few new projects as well). I didn’t realize that I should check the number of teeth on the saw blade to figure out if I’ll get more of a clean and slow cut or not. That’s an important part of the overall picture, so I’m glad you started with this… the extra detail below is also helpful to make sure I’m getting the right specific tool and teeth for the job. Do you have a recommendation for a good general purpose blade, or would you go with something really specific for each job?

Hi Aly,

Thank you for the comment and question! Choosing a saw blade is always going to involve the quality of result you want. So for general purpose woodcutting that doesn’t require a glassy smooth cut, the Diablo brand combination blade is excellent. If you’re cutting expensive hardwoods, then you will undoubtedly be more choosy about the saw blade you use.

Happy building!

Greg