Page Contents

Choosing A Circular Saw

So, you're choosing a circular saw for the first time. Awesome!

Buying new tools is one of my favorite activities. At least until I get to the store and realize there are dozens of options. I find myself feeling like a small child in a candy store, unable to make a decision.

It's surprising how many different circular saws there are. You may be asking:

- How much power do I need?

- Does the weight of the saw really matter?

- How about the bevel angle?

- Does it matter what the saw is made out of?

As a beginner, you should consider what kind of projects you want to make.

- Do you see yourself recycling old pallets into usable outdoor furniture?

- Perhaps you have plans to construct an outdoor deck?

- Are bookcases to line the walls of your den on your creative projects list?

- Maybe even bunk beds for your children or grandchildren?

Identifying your woodworking goals can help you decide which circular saw will meet your needs.

For example: Let's say your only woodworking goal is to recycle old pallets into usable wooden furniture and home décor. You might choose a lower quality saw because Pallet furniture usually does not require smooth precision cuts to be successful. If you plan to make furniture or bookcases from quality hardwoods. You may choose a higher quality saw that is more likely to make smooth and accurate cuts.

The reality is simply this, any circular saw that keeps the blade rotating is going to cut wood. However, the different features for each circular saw brand will affect:

- safety

- how easy it is to use the tool

- how smooth it cuts wood

- the expected longevity of the saw.

I have listed the features below that we will talk about in more detail throughout the rest of this article. I hope this will give you a clear idea of what to look for in the saw you purchase.

- Power/Amps

- Cordless or Corded

- Weight of the saw

- Blade size Depth of cut:

- Arbor size

- Bevel Stops, and Max Angle:

- Quality construction

- Shoe

- Retracting Lower Blade Guard

- Length of cord

- Carrying/storage case

- Dust Collection Port

- Electric Brake

Circular Saw Amps—What are amps, why should I care?

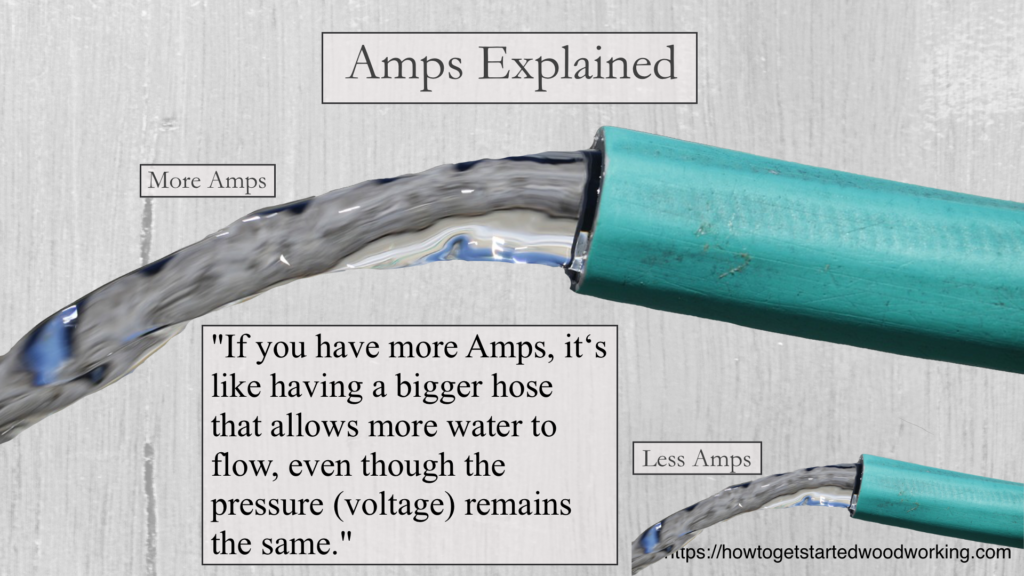

The power of a circular saw is measured in volts and amps.

This is kind of confusing for a lot of people. Just think of voltage as the water pressure in a garden hose. Amps, on the other hand, are the amount of water flowing through the hose. If you have more Amps, it's like having a bigger hose that allows more water to flow, even though the pressure (Voltage) remains the same.

The Amps determine how long your motor can operate without overheating (overheating is bad and can ruin your tool).

So, if you plan on using your saw repeatedly over an extended time, like building an outdoor deck. Then a circular saw with a 15 amp motor is a good idea.

If you only want a saw for cutting a few lengths of lumber at a time, and the saw will have plenty of time to cool down in between uses. Then a 10 or 12 amp circular saw could be very adequate.

Should I get a Cordless or Corded Circular Saw?

There's a huge variety of circular saws, and when you add cordless saws on to the list, the choices seem almost endless.

With almost every type of tool, the decision will come down to your intended use.

There are many good quality cordless circular saws. For doing a lot of cutting with dimensional lumber like 2 x 4's to 2 x 12's, trim, and molding, they work well and may suit your needs perfectly.

However, for the beginning woodworker, I recommend a corded circular saw.

Corded circular saws will give you the most power and versatility for any direction you want to take your new craft. For sustained power and long term working ability, the corded circular saw is a better choice.

Does the Weight of a Circular Saw Matter?

As you're shopping, you'll notice saws weighing from 6 ½ to nearly 15 pounds! Oh my gosh! How can there be such a difference!

There are excellent tools in almost every weight category, and individual preference is most important here.

- My daughter is about 5' 6" and weighs 118 pounds. She prefers using a very lightweight saw, mostly because carrying it across the shop is more manageable, not because sawing is easier.

- I'm 6' 1" and 205 pounds. The weight of a saw doesn't matter very much to me. I've made a lot of cuts with circular saws over the years. I have never experienced any fatigue from using a heavy saw.

Unless you are a contractor making hundreds of cuts, the weight of the saw will probably not be an issue for you. When using a circular saw, the weight of the saw is supported by the wood you are cutting, so you're only holding the full weight when you pick it up and set it back down.

Circular Saw Blade Sizes

The most common blade size for a circular saw is 7 ¼ inches. I recommend this size because it is most versatile. The seven and one quarter inch blade can cut up to 2 7/16 inches deep at 90°, and 1 7/8 eighths inches at 45°. This will allow the user to cut 2-inch dimensional lumber without a problem.

Smaller circular saws are available, but the blade size and available power will limit your use. Many of these small saws are made for a specific purpose, such as cutting molding and trim for finishing work.

What Is An Arbor On A Saw?

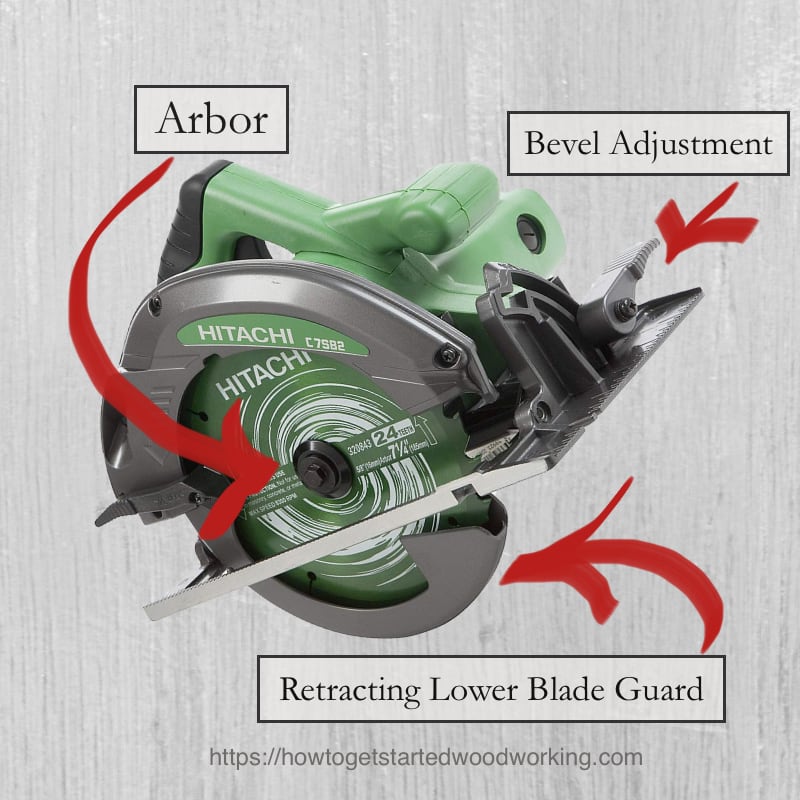

What is an arbor? On the circular saw, it is the axle, spindle, or shaft, to which the blade is mounted. (Not a shady garden arch thing) The standard size for an arbor is 5/8 inch.

You may find a saw that has a diamond-shaped arbor. On "worm drive" circular saws, the arbor is diamond-shaped because the worm drive saws create an enormous amount of torque.

Worm drive saws are used a lot by contractors that need to power through all types of lumber, even wet lumber with lots of knots. They need a saw that will not be destroyed by many hours of heavy use.

Bevel—What is it?

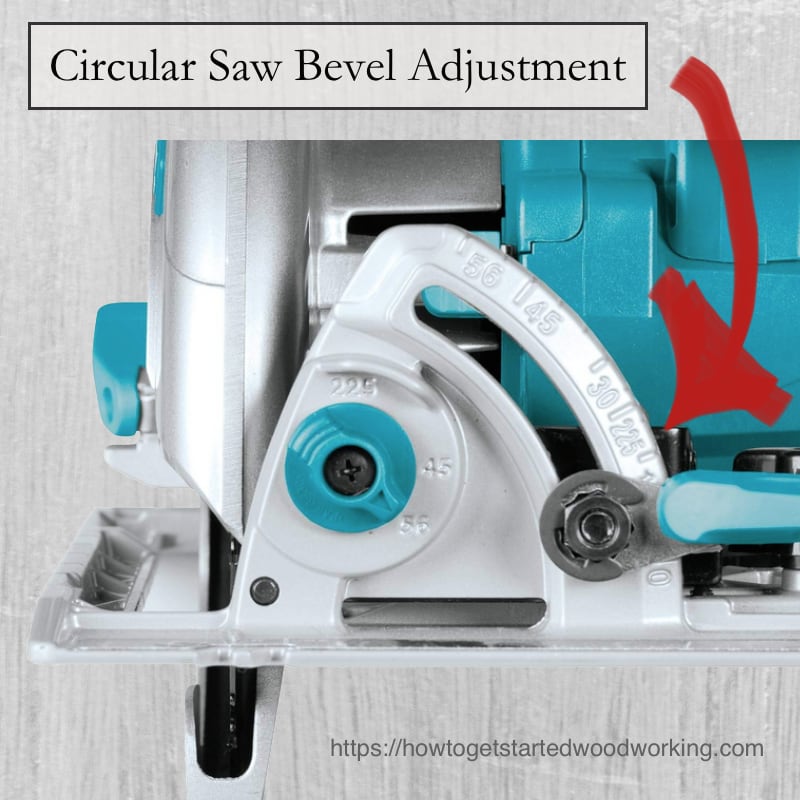

On a circular saw, the bottom plate or shoe can be adjusted so the saw can cut from 0° or vertical up to 45°. The angled cut is called a bevel. When purchasing your saw, be sure to see how many degrees of bevel the saw can cut.

It is also essential to pay attention to the adjustment mechanism on the shoe or bottom plate. Better saws will use levers that easily lock and unlock the shoe for adjustment. Lesser saws use a twisting screw knob that I have found to be more challenging to adjust.

Bevel stops are another feature to consider. Most of the better saws will have preset bevel stops at 22.5° and at 45°. These really help with quickly and accurately setting the bevel on your saw.

Quality of Construction

We could go into extreme detail about the different materials used in the production of power tools. But the reality is, you get what you pay for.

Are you purchasing a saw with plastic as the only material listed in its construction? It will not last as long on average as a saw that contains aircraft aluminum or magnesium as its construction material.

Purchasing a circular saw from one of the following manufacturers will almost always guarantee a quality tool that will last for many years. My recommendations are:

Sure, there are other brands, and maybe many of them are great, but these are brands I have experience with and have never had any problems with either.

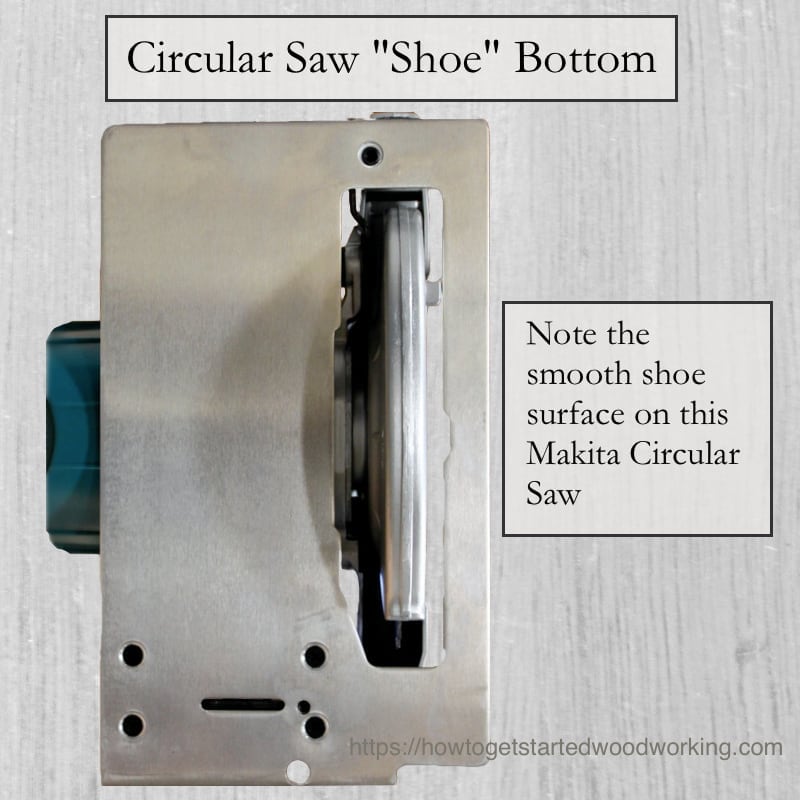

Circular Saw Shoe

When you are choosing your saw, look at the bottom of the shoe. This is the part of the tool that slides across the wood you are cutting.

- Make sure the base is smooth and stable (I prefer magnesium or aircraft aluminum)

Lower quality circular saws have a shoe or bottom plate, made from thin steel. Although these can cut well, you should inspect to make sure there are no rough edges on the shoe that will scratch your project while you are cutting. These scratches may cause you a lot of extra effort when you are sanding and finishing later.

Retracting Lower Blade Guard

The lower blade guard is designed to keep the rotating sawblade covered and is supposed to move smoothly out-of-the-way as you move the saw through the wood you're cutting.

To evaluate a circular saw for purchase, be sure the saw is unplugged. Slide your finger along the bottom shoe of the saw next to the blade, pushing the retracting lower blade guard as you go.

- Does the blade guard retract smoothly?

- Or, do you find it catching, forcing you to push harder to get it to move?

Sticky retracting lower blade guards have been a problem with circular saws for many years. If the blade guard catches as the blade enters the wood, it can ruin the smooth cut as you force the saw to get the blade guard moving, giving you a rough and often crooked cut.

The standard solution for some woodworkers has been putting a wedge in the blade guard. (see photo) This is a hazardous practice that has caused numerous trips to the emergency room over the years.

Again, higher quality saws tend to have a smoother action than their cheap counterparts.

Length of cord, does it matter?

Yes, it does matter. Truthfully though, there are only a couple of situations where this is a safety concern. Mostly it is a personal frustration with manufacturers "going cheap" on the cord, so let me give you an example:

Imagine you have a circular saw with a 6-foot cord. For your project, you need to make an 8 foot cut down the center of a plywood sheet.

When cutting, the cord is dragged over the edge of the plywood.

This is where the trouble starts. When the plug catches on the edge of the plywood, you still have 2 feet left to cut.

Unfortunately, you can't saw any farther, nor can you reach your cord because you are 6 feet away from it.

If your cord is 8 feet long or longer, then you can safely finish sawing all 8 feet without the plug getting caught.

Of course, there are ways to work around this.

- You can get an assistant to help you manage the cord.

- You can think ahead and suspend the cord above your workstation.

- Sometimes you can move the cord to the side of the board, so it follows along with you.

Despite these options, though, if you work alone, having a short cord causes problems. That is why I recommend purchasing a saw with a minimum cord length of 8 feet.

Carrying/Storage Case

Moving tools from one place to another and efficiently storing them are valuable features that will make woodworking a better experience for you.

Most of the quality tool manufacturers now include either a plastic storage case or nylon/canvas carrying bag. I do prefer the hard plastic cases, but this is merely personal preference. The main issue is keeping your tool and all of its accessories in one location.

Circular Saw Electric Brake

Many of the newer saws are featuring an electric brake that assists in stopping the saw blade from turning as soon as you release the power. This is a nice feature since it is much more difficult to injure yourself with a saw blade that is not turning.

It is a good safety practice to wait until the blade has completely stopped rotating before setting the tool down.

The electric brake is a very welcome safety addition. However, anyone that uses circular saw must realize that this tool can easily remove fingers, hands, or any other body part. So always use every safety precaution regardless of the safety features that are installed on your tools. If you're not sure what those are, check my post on woodshop safety here.

Dust collection port

I wish every circular saw had a built-in dust collection port. Unfortunately, these are rarely found on circular saws, and you would have to move over to a Track Saw where dust collection is more common.

Did you find a circular saw with a dust collection port? Make sure you have the proper adapters to connect it with your shop vacuum or other dust collecting system. You can find more help with dust collection from my post, "Best Woodshop Vacuum Systems."

Please make sure you always keep your health in mind and wear a dust mask or respirator appropriate for the situation.

Summary

In this post, we have looked at 13 features to consider when choosing your first circular saw.

My recommendations to look for in your first saw are:

- Enough power for the projects you have in mind

- Corded saw

- Weight of the saw appropriate for your personal size or preference

- 7 1/4" Blade and 5/8" Arbor

- Easy to adjust bevel Levers, not screws

- Aluminum or magnesium in construction materials

- Cast Aluminum or Magnesium "Shoe"

- Smooth action on the Retracting Lower Blade Guard

- Minimum 8-foot long cord

- Some form of carrying case

- Electric Brake and Dust collection is helpful but not essential

It's fun to shop when you know what you are looking for.

Hopefully, my suggestions in this post will help you make your decision with confidence. For even more help, see my post "Corded Circular Saw Review."

Please share your circular saw experiences with me in the comments section. I will love to hear if this post has been of help to you.

Do you know someone shopping for a circular saw? Please share this article with them.

I recently retired and started dabbling with wood in my garage as I have a lot of time and little to do. I managed to craft a few simple items but they are far from perfect. I’ve been trying to learn about the art of wood crafting and looking for a circular saw. I’m glad I came accross this article because now I have a better understanding of what I’m looking for. Thank you so much for sharing!

Congratulations on your retirement Afonso! I’m glad you have time to create things with wood. Wood projects are rarely perfect to the maker. I hope you find great satisfaction in the process.

lovely article and very educative for all those out there looking for saws for their businesses or for home purposes. I really loved how detailed each point was, this aritcle is all we need to choose the best saw without excessive time wasting on the internet. I would definetely recommend this article to my friends.

My question is what is the best saw to cut trees down with deep roots.

Hello Edward, thanks for your kind remarks. To answer your question, the saw to use for cutting down a tree is a chain saw. To remove tree roots and the stump can require some serious effort. Depending on your location, you may need to hire a professional tree removal service. Especially if there are electrical lines running above, or any other public utilities running under ground near the tree.

Hi Greg

Thank you very much for this detailed article on circular saws, as this is an important tool for the serious Do-It-Yourself person. I have used circular saws in the past and they can give you a supreme straight cut, especially if you want to build a piece of furniture or want to construct a fence or even a shed. I really like how you have broken down what to look for in a circular saw. My favourite is Bosch as they are comfortable and easy to use; cut good as well.

I got to admit all the imperial measurement of saw sizes is off-putting, as I find saw sizes in mm to be easier and will give more precision to your cuts. Do you know where you can get metric circular saws.? if you are doing a lot of wood cutting I would recommend an extractor and a dust mask and goggles, otherwise the wood dust can seriously irritant you nose and eyes.

A great article

Antonio

Thanks Antonio! I appreciate your comments and questions! I agree with you about Imperial measurements. Finding a tool with metric measurements is going to be difficult in the USA. A European model would be great, but then of course it will be wired for 220.

I definitely recommend the respirator and goggles too. Safety is always of vital importance.

Cheers!

Oh this is SUCH a timely post. Thank you so much. I have two circular saw’s and one I have to give back to my EX husband. Now I am going to use your list and examine both of them with extreme care. One of them is going to be hidden away and one of them will be going back to my ex-husband. Guess which one I’m going to be hiding away?

Hi Feochadan! I’m so glad my post could be of help to you! If you find yourself in a quandary let me know what brand of saws they are, and I’ll be glad to help you choose the best one. I hope things go well for you!

Best regards!

This is a great article with detailed information here. I would like to add, so if I were interested in buying my first circular saw, I would also like to know the differences in features between a high priced and a lower priced circular saw. And if there are any saws that are manufactured for left-handed users. These little bits of information would be appreciated. Anyways, great information you got there and thanks for sharing.

Hi and thanks for your questions! The main differences between high and low priced circular saws are the materials used to make them. The old saying “You get what you pay for,” holds true in the tool world. You can expect cheap circular saws to have a thinner steel shoe or bottom plate, less accurate and harder to adjust bevel adjustments, and a lot more plastic components in their construction. There are a few left hand circular saws manufactured one of them is Milwaukee’s 6391-21 circular saw. You can read about it in my circular saw review article here: https://howtogetstartedwoodwor…

Thanks again and happy woodworking!